Blocking is a crucial aspect of construction that refers to the installation of short pieces of framing lumber. These pieces are usually between wall studs or other structural elements. The main purpose is to provide support for fixtures, cabinets, or drywall.

It ensures that elements like shelves and cabinets have a solid anchor. This is especially important during drywall estimation as accurate blocking can prevent future issues. Proper blocking improves structural integrity and stability, enhancing safety and durability.

Definition of Blocking

Blocking refers to the process of inserting short, specific lengths of lumber between structural elements such as wall studs. These pieces provide additional support and anchoring for various installations, ensuring that items like cabinets and fixtures are securely mounted.

Moreover, it plays a critical role in enhancing the overall structural integrity of the building. Properly installed blocking prevents future issues by reinforcing areas where additional support is needed, thereby contributing to the safety and durability of the construction. This is especially noticeable during tasks like drywall installation, where accurate blocking can make a significant difference.

Purpose of Blocking

Its primary purpose is to offer additional support for fixtures, cabinetry, and drywall. By providing a solid anchor point, it ensures that these elements are securely attached to the structure. This is crucial for the safety and durability of the installations.

Another key objective is to improve the building’s structural integrity. Reinforcing areas that require extra support helps prevent future issues. This is particularly important during drywall installation, as accurate support placement can significantly impact the outcome. Properly installed supports contribute to a long-lasting and stable construction.

Common Blocking Materials

Common materials used for blocking in construction include wood, metal, and engineered lumber. Wood, such as pine or fir, is widely preferred for its ease of installation and availability. It is often cut into short lengths that fit snugly between studs or other framing members. Metal blocking, usually made of steel or aluminum, offers increased durability and fire resistance.

Engineered lumber, such as oriented strand board (OSB) or laminated veneer lumber (LVL), can provide enhanced strength and stability. These materials are designed to handle higher loads and are often used in critical areas requiring extra support. The choice of material typically depends on the specific needs and requirements of the construction project.

Techniques for Installing Blocking

It involves several techniques to ensure proper installation. One method is to use a measuring tape to accurately determine the length of each piece of material. This ensures a snug fit between the structural elements, providing the necessary support. Predrilled holes can be used for easier installation, especially when working with metal or engineered materials.

Another technique is to stagger the placement to avoid weakening the studs or framing members. This helps distribute the load more evenly across the construction. Additionally, using a level during the installation process ensures that the supports are placed correctly for optimal performance. Proper spacing is essential to provide maximum stability and strength.

Importance of Proper Blocking Practices

Proper blocking practices are essential for ensuring the safety and longevity of a construction project. When accurately placed, these supports guarantee that fixtures, cabinets, and other installations remain securely anchored. This prevents future structural issues and potential hazards. Using correct techniques like measuring and leveling adds to the reliability of the installation.

Furthermore, good practices prevent damage to framing members by distributing loads evenly. This reinforces the overall structural framework, enhancing the building’s stability. Employing the right materials and methods ensures that every component of the construction is well-supported, contributing to a durable and safe structure.

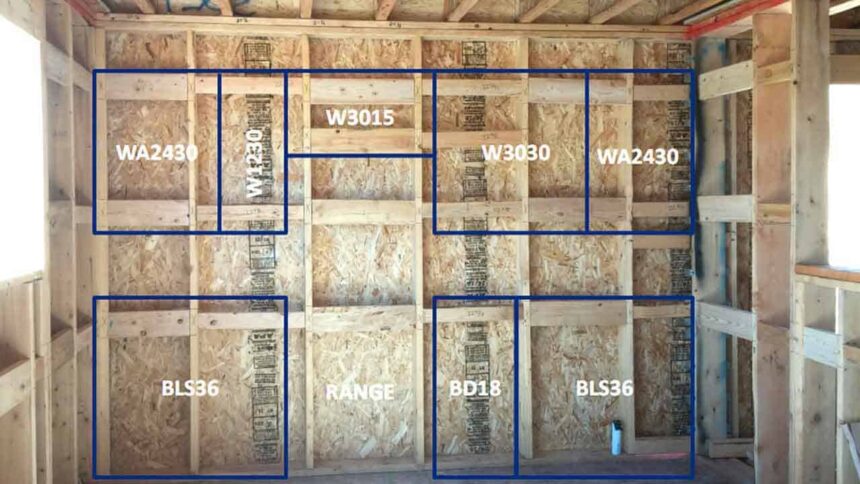

Blocking in Framing Construction

Blocking in framing construction involves placing short pieces of lumber between studs or other structural elements. The primary aim is to provide extra support for drywall, fixtures, and other installations within the framed structure. This ensures that mounted items stay firmly in place, preventing potential issues that could arise from unsecured installations.

Moreover, it helps in reinforcing the overall stability of the framed structure. Proper installation techniques, such as accurate measuring and leveling, are crucial to ensure each piece fits securely. By doing so, it enhances the durability and safety of the construction, contributing to a more robust and long-lasting framework.

Blocking in Concrete Construction

In concrete frameworks, these supports are crucial for securing bolts, rebar, and formwork. They help maintain the stability of poured concrete by ensuring everything stays in place.

When properly installed, they enhance the structure’s integrity. This prevents shifts that may lead to cracks or weaknesses. Proper spacing and measuring are vital here too. This ensures the material is evenly supported. It ultimately results in a durable and lasting construction.

Challenges with Blocking

One challenge involves ensuring precise measurements. If not measured correctly, the supports can be misaligned. This compromises structural integrity. It’s essential to use accurate tools. Misalignment during installation can cause significant issues.

Another issue is working with various materials. Wood, metal, and engineered lumber each have distinct properties and requirements. This adds complexity to the installation. Different techniques may be needed for each material, making the process more demanding. Proper preparation and understanding of the materials are crucial for successful blocking installation.

Innovations in Blocking Methods

Advancements in technology have led to improved techniques for installing supports. Prefabricated blocking systems streamline the installation process. They can be quickly fitted into place, saving time and reducing labor costs. New materials, designed for greater strength and durability, are also being used.

In addition, there are now advanced tools available that provide precise measurements. This ensures more accurate placement of supports. These innovations result in a more reliable and efficient construction process. Improved methodologies significantly enhance the stability and longevity of the finished structure.

Conclusion

Blocking is a crucial element in construction. It ensures that every part of the structure is stable and able to support additional loads. Accurate measurements and proper installation techniques are vital for effective blocking. Using the right materials also contributes to the longevity and safety of the building.

Innovations have made the process easier and more efficient. Prefabricated systems and advanced tools save time and reduce errors. By following these methods, construction projects benefit from improved stability and durability. Good practices in blocking lead to better, safer structures that stand the test of time.