Introduction: Importance of Shale Shaker Screens in Drilling Operations

Shale shaker screens play a crucial role in the drilling industry. These screens are designed to separate solid particles from the drilling fluid, ensuring the efficiency and effectiveness of the drilling process. Proper selection of high-quality shale shaker screens can significantly enhance operational performance. This article explores leading Shale Shaker Screens Suppliers, their product offerings, and why choosing the right one matters for optimal drilling.

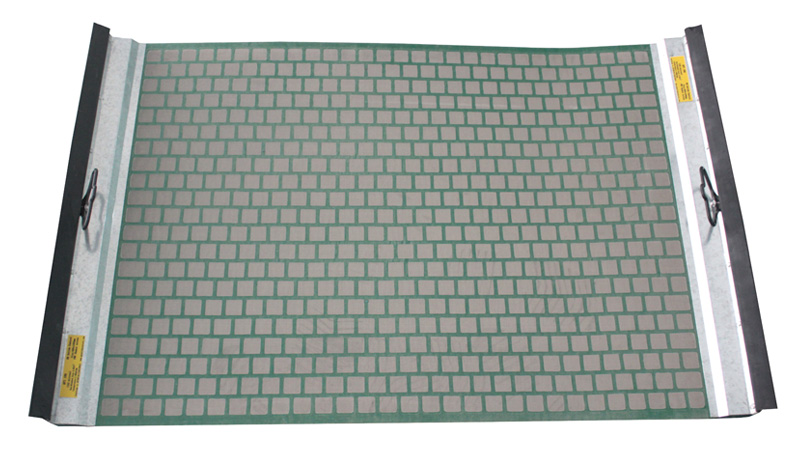

What are Shale Shaker Screens?

Shale shaker screens are integral to the drilling fluid recycling system. They are used to filter out cuttings from the drilling fluid, allowing the cleaned fluid to be reused. This process minimizes waste and enhances drilling efficiency. Shale shaker screens come in various designs, including flat and pyramid styles, and are made from high-quality stainless steel mesh or synthetic materials to ensure durability and performance.

Leading Shale Shaker Screens Suppliers

Several suppliers offer top-notch shale shaker screens that meet the industry’s demanding requirements. When selecting a supplier, it’s essential to consider their experience, product quality, and customer support. Below are some of the leading suppliers globally:

1. Brand X – Industry Leader in Screen Technology

Brand X has established itself as a leading supplier of shale shaker screens, offering advanced technology and high-performance materials. Their screens are known for durability and efficiency, with options designed for various drilling environments. Brand X’s commitment to research and development ensures their products meet the latest industry standards, making them a trusted name in shale shaker screens.

2. Brand Y – Reliable and Cost-Effective Solutions

Brand Y is renowned for providing reliable and cost-effective shale shaker screens. Their screens are designed to minimize downtime and optimize the drilling process. They offer a wide range of products that are compatible with various shale shaker models, making them a popular choice for drilling operations worldwide. Brand Y is known for its competitive pricing and excellent customer service.

3. Brand Z – High-Quality Screens for Harsh Environments

Brand Z specializes in manufacturing shale shaker screens that perform well in extreme conditions. Their products are designed for high-temperature and high-pressure environments, ensuring excellent filtration efficiency. Brand Z’s screens are built to last, even under the most challenging drilling conditions, making them a preferred choice for operators in harsh drilling environments.

Key Features to Look for in Shale Shaker Screens

When selecting a shale shaker screen, several factors should be considered to ensure optimal performance:

- Mesh Material: Stainless steel is the most common material for shale shaker screens due to its strength and resistance to corrosion.

- Durability: A high-quality screen will last longer, reducing downtime and maintenance costs.

- Mesh Size: The mesh size must be suitable for the specific drilling environment and the type of material being filtered.

- Compatibility: Ensure the screen is compatible with the shaker unit to maximize performance and efficiency.

Benefits of High-Quality Shale Shaker Screens

High-quality shale shaker screens offer several advantages, including:

- Increased Drilling Efficiency: The primary function of shale shaker screens is to separate cuttings from drilling fluid, ensuring that the fluid remains clean and reusable. This enhances overall drilling efficiency.

- Reduced Costs: With superior durability, high-quality screens reduce the need for frequent replacements and maintenance, leading to cost savings in the long run.

- Enhanced Operational Performance: Shale shaker screens that are properly matched to the drilling environment improve the overall performance of the drilling rig, resulting in higher productivity.

How to Choose the Best Shale Shaker Screens Supplier

Choosing the right supplier for shale shaker screens is critical for the success of your drilling operation. Here are a few key points to consider:

1. Product Quality and Standards

Look for suppliers that adhere to industry standards and provide detailed specifications for their products. This ensures that the shale shaker screens are durable, reliable, and capable of performing under the required conditions.

2. Customization Options

Many leading suppliers offer customization options to meet the specific needs of your drilling operation. Whether you need a particular mesh size or a custom design, it’s important to choose a supplier that can tailor their products to your needs.

3. Customer Service and Support

A reliable supplier should offer excellent customer service and technical support. They should be able to assist with installation, maintenance, and troubleshooting, ensuring that your shale shaker screens function at optimal levels throughout their lifespan.

4. Cost and Value

While cost is an important consideration, it should not be the only factor in your decision-making process. Evaluate the overall value offered by a supplier, including product quality, customer service, and long-term durability.

Maintenance and Care of Shale Shaker Screens

Proper maintenance and care of shale shaker screens are essential for ensuring their longevity and performance. Regular cleaning, inspection for wear and tear, and prompt replacement of damaged screens are necessary to keep the shaker system functioning efficiently. A well-maintained shale shaker screen can last longer and continue to perform effectively in separating solid particles from drilling fluids.

Conclusion: Choosing the Right Shale Shaker Screens Supplier

Selecting the right shale shaker screen supplier is crucial for optimizing the drilling process. Leading Rotary Slips suppliers offer a range of high-quality screens that are durable, efficient, and cost-effective. By considering factors such as product quality, customer service, and compatibility with your drilling equipment, you can ensure the success of your drilling operation. Investing in the best shale shaker screens will not only improve operational efficiency but also reduce long-term maintenance costs, making it a smart choice for drilling professionals worldwide.