Tunnel linings construction is a critical aspect of infrastructure development, ensuring the structural integrity and safety of underground passages. Whether it’s for transportation, utility networks, or mining operations, the construction of reliable and durable tunnel linings is paramount. As the demand for efficient and cost-effective tunnel infrastructure continues to grow, the need for innovative solutions has become increasingly evident.

Importance of Innovative Solutions in Tunnel Linings Construction

In the face of complex geological conditions, varying soil compositions, and stringent safety regulations, traditional tunnel linings construction methods may fall short in meeting the evolving requirements of modern projects. Innovative solutions that can enhance the performance, longevity, and cost-effectiveness of tunnel linings are crucial for the success of any underground infrastructure endeavor.

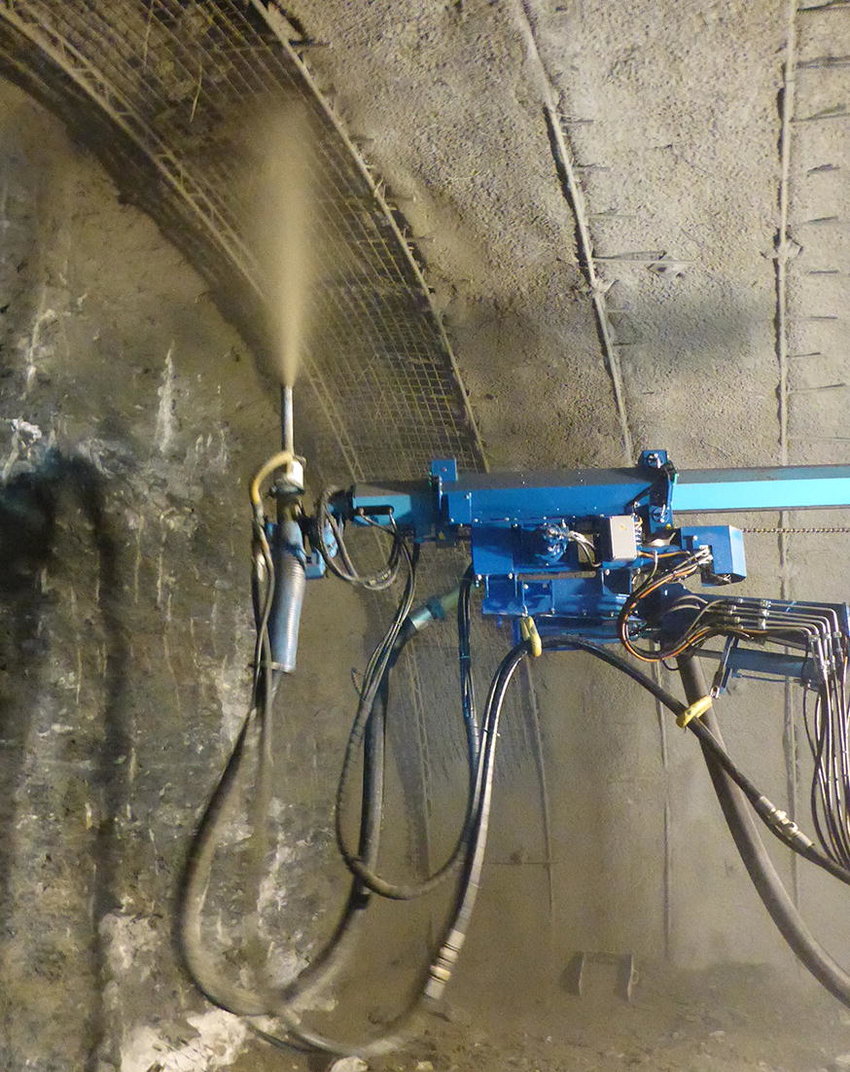

Understanding Mining Shotcrete Solutions

One such innovative solution that has gained significant traction in the tunnel linings construction industry is mining shotcrete solution. Shotcrete, also known as sprayed concrete, is a versatile construction material that can be applied directly to tunnel walls and surfaces, providing a durable and reinforced lining. Mining shotcrete, in particular, is designed to address the unique challenges encountered in mining and underground construction environments.

Advantages of Using Mining Shotcrete Solutions in Tunnel Linings Construction

- Rapid Application: Mining shotcrete can be applied quickly and efficiently, allowing for faster construction timelines and reduced downtime.

- Improved Structural Integrity: The specialized formulation of mining shotcrete provides enhanced strength, durability, and resistance to weathering and chemical exposure, ensuring the long-term stability of tunnel linings.

- Enhanced Safety: Mining shotcrete solutions can contribute to improved worker safety by creating a reinforced and secure tunnel environment, reducing the risk of rockfalls and other hazards.

- Cost-Effectiveness: The efficient application and superior performance of mining shotcrete can lead to reduced overall construction costs and maintenance requirements.

- Adaptability: Mining shotcrete can be tailored to suit a wide range of geological conditions and project requirements, making it a versatile solution for diverse tunnel linings construction scenarios.

Challenges in Implementing Mining Shotcrete Solutions

While the advantages of mining shotcrete solutions are substantial, there are also challenges that must be addressed for successful implementation:

- Specialized Expertise: The effective use of mining shotcrete requires specialized knowledge and skills, necessitating the involvement of experienced contractors and professionals.

- Material Compatibility: Ensuring the compatibility of mining shotcrete with other construction materials and existing tunnel structures is crucial to maintain structural integrity and avoid compatibility issues.

- Environmental Considerations: The application of mining shotcrete may involve environmental factors, such as dust control and waste management, that must be carefully managed.

- Quality Control: Stringent quality control measures are essential to ensure the consistent performance and reliability of mining shotcrete solutions.

Case Studies Showcasing Successful Implementation of Mining Shotcrete Solutions

- Tunnel Rehabilitation in a Major Metropolitan Area: A large-scale tunnel rehabilitation project in a major metropolitan area utilized mining shotcrete to reinforce and restore the structural integrity of aging tunnel linings. The rapid application and superior strength of the shotcrete solution allowed for efficient completion of the project, with minimal disruption to the surrounding infrastructure.

- Mining Tunnel Construction in a Remote Location: In a remote mining operation, the use of specialized mining shotcrete enabled the construction of a complex tunnel system through challenging geological conditions. The adaptability and durability of the shotcrete solution contributed to the successful and safe completion of the project.

- Utility Tunnel Upgrades in an Urban Environment: A utility tunnel upgrade project in a densely populated urban area employed mining shotcrete to enhance the structural integrity of the existing tunnel linings. The cost-effectiveness and ease of application of the shotcrete solution were key factors in the successful implementation of the project.

Best Practices for Enhancing Tunnel Linings Construction Using Mining Shotcrete Solutions

- Comprehensive Planning: Engage in thorough planning and feasibility assessments to ensure the optimal selection and implementation of mining shotcrete solutions.

- Collaboration with Experts: Collaborate with experienced contractors, engineers, and industry experts to leverage their expertise and ensure the proper application of mining shotcrete.

- Rigorous Quality Control: Implement robust quality control measures, including material testing, application monitoring, and performance evaluation, to maintain the high standards of mining shotcrete solutions.

- Continuous Innovation: Stay informed about the latest advancements in mining shotcrete technology and actively explore opportunities for continuous improvement and optimization.

- Effective Project Management: Employ effective project management practices, such as clear communication, risk mitigation, and proactive problem-solving, to ensure the successful implementation of mining shotcrete solutions.

Available Mining Shotcrete Solutions in the Market

The market offers a wide range of mining shotcrete solutions, each with its own unique characteristics and applications. Some of the prominent options include:

| Solution | Key Features |

| Fiber-Reinforced Shotcrete | Enhanced tensile strength, impact resistance, and crack control |

| Accelerated Shotcrete | Rapid setting and early strength development for faster construction |

| Specialty Shotcrete Mixes | Customized formulations for specific geological conditions or performance requirements |

| Self-Compacting Shotcrete | Improved flow and reduced rebound for efficient application |

| Wet-Mix Shotcrete | Consistent quality and reduced dust generation during application |

Future Trends in Mining Shotcrete Solutions for Tunnel Linings Construction

As the demand for innovative and sustainable tunnel infrastructure solutions continues to grow, the future of mining shotcrete in tunnel linings construction is expected to evolve in the following directions:

- Advancements in Material Science: Ongoing research and development in material science will likely lead to the creation of even stronger, more durable, and more environmentally friendly mining shortcrete formulations.

- Automation and Robotics: The integration of automation and robotic technologies in the application of mining shotcrete can enhance efficiency, consistency, and worker safety.

- Sustainability and Eco-Friendliness: The focus on sustainable construction practices will drive the development of mining shotcrete solutions with a lower environmental impact, such as those with reduced carbon footprints or increased use of recycled materials.

- Integrated Project Delivery: The adoption of collaborative project delivery methods, such as design-build or integrated project delivery, will enable seamless integration of mining shotcrete solutions into the overall tunnel linings construction process.

- Digital Transformation: The incorporation of advanced digital technologies, such as Building Information Modeling (BIM), real-time monitoring, and predictive analytics, will optimize the planning, execution, and maintenance of tunnel linings constructed with mining shotcrete.

Conclusion

In the ever-evolving landscape of tunnel linings construction, the innovative use of mining shotcrete solutions has emerged as a game-changer. By harnessing the rapid application, superior strength, and cost-effectiveness of mining shotcrete, you can unlock new possibilities for your tunnel infrastructure projects. As you navigate the challenges and opportunities in this dynamic industry, stay at the forefront of the latest advancements and best practices to ensure the successful implementation of mining shotcrete solutions that will shape the future of tunnel linings construction.