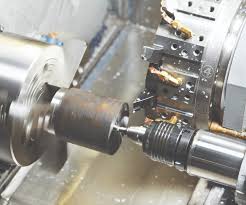

When it comes to precision machining, lathes are indispensable tools that help shape and cut materials to exact specifications. However, investing in new lathes can be costly, making used lathes a viable and cost-effective alternative for many businesses. At The Equipment Hub, we understand that selecting the right used lathe involves more than just cost considerations—it’s about making an informed decision that enhances your operations. In this detailed guide, we will delve into the benefits of purchasing used lathes, essential considerations when buying, and practical tips to ensure you make a sound investment.

The Benefits of Buying Used Lathes for Sale

Significant Cost Savings

One of the most appealing reasons to opt for used lathes is the considerable cost savings. New lathes can represent a substantial financial outlay, which might not always fit within a company’s budget constraints. By choosing a used lathe, you can acquire high-quality equipment at a significantly lower price. This allows you to allocate funds to other crucial areas of your business, such as expanding your product line or investing in technology upgrades. For small to medium-sized enterprises, this can make a big difference in financial planning.

Immediate Availability

Used lathes are often available for immediate purchase, unlike new machines that might have long lead times due to manufacturing and shipping. This is particularly beneficial if you need to replace a faulty lathe urgently or if you are looking to scale up production quickly. Immediate availability means less downtime and a faster return to optimal productivity, which can be crucial in meeting tight project deadlines or unexpected production increases.

Proven Reliability

Many used lathes come from well-regarded manufacturers known for their durability and performance. These machines have been tested in real-world conditions and have a track record of reliability. By purchasing from a trusted dealer like The Equipment Hub, you can be confident that the lathe you’re considering has been rigorously inspected and maintained. This assurance of quality helps avoid the risks associated with buying less reliable or untested equipment.

Lower Depreciation

New lathes experience rapid depreciation, with their value decreasing sharply in the initial years. Used lathes, having already undergone most of their depreciation, offer a more stable value. This makes purchasing a used lathe a more economical investment in the long run, as you can benefit from high-quality machinery without worrying about its value plummeting shortly after purchase. This can be particularly advantageous for businesses aiming to maximize their capital expenditures.

Key Considerations When Buying Used Lathes for Sale

Machine Condition

The condition of a used lathe is crucial in determining its potential value and performance. It is essential to conduct a thorough inspection of the machine, checking for signs of wear such as rust, damage, or excessive play in moving parts. Key areas to focus on include the bed, carriage, spindle, and tool holders. Assessing these components will help ensure that the lathe is in good working order and capable of meeting your machining needs.

Maintenance and Service History

Request detailed maintenance and service records for the lathe. Regular maintenance and timely repairs are strong indicators of a well-cared-for machine. A lack of maintenance documentation could suggest potential issues that might arise after purchase. By reviewing the service history, you can gain insights into the lathe’s condition and the extent of any past issues, helping you make a more informed decision.

Specifications and Features

Ensure that the used lathe meets your specific machining requirements. Evaluate the machine’s specifications, such as its maximum spindle speed, tool capacity, and the size of workpieces it can handle. It’s important to confirm that the lathe’s capabilities align with your production needs. Additionally, check for any special features or attachments that might be beneficial for your operations, such as CNC controls or specialized tooling.

Reputation of the Seller

Purchase from reputable dealers or sellers who specialize in used machinery. Established dealers like The Equipment Hub adhere to rigorous standards to ensure that the equipment they offer is of high quality and well-maintained. Check reviews, ask for references, and verify the seller’s credentials to ensure you’re dealing with a trustworthy source. A reputable dealer will provide transparency about the machine’s condition and history, giving you confidence in your purchase.

Warranty and Support

While used lathes typically come with shorter warranties compared to new machines, some dealers offer limited warranties or support services. Understand the terms of any warranty or support provided and what is covered. Access to support services can provide peace of mind, addressing any issues that may arise post-purchase and ensuring that you have assistance if needed.

Potential for Upgrades

Consider whether the used lathe can be upgraded or retrofitted to enhance its performance or adapt to new requirements. Some older models can be fitted with modern control systems or additional features, extending their useful life and improving their functionality. Upgrades can add significant value to a used lathe, making it a more versatile and valuable asset for your operations.

Tips for Finding the Best Used Lathes for Sale

Conduct Thorough Research

Before making a purchase, conduct comprehensive research on different models and brands of used lathes. Review specifications, features, and user reviews to assess the performance and reliability of various options. Comparing different lathes helps identify the best fit for your needs and budget, allowing you to make a more informed decision.

Verify Machine History

Request detailed documentation of the lathe’s history, including its previous usage, repairs, and any modifications. This information provides insight into the machine’s overall condition and helps identify any potential issues. A well-documented history ensures transparency and aids in making a confident purchase.

Arrange for a Test Run

If possible, arrange for a demonstration or test run of the used lathe. Observing the machine in operation allows you to assess its performance and verify that it meets your requirements. Testing the machine also helps identify any potential issues, ensuring that you are making a sound investment.

Negotiate the Price

Don’t hesitate to negotiate the price of the used lathe. Many sellers are open to reasonable offers, especially if the lathe has been on the market for some time or if you’re purchasing multiple machines. Negotiating can help you secure a better deal and maximize your investment.

Explore Financing Options

If purchasing a used lathe outright is not feasible, explore financing options. Many dealers offer flexible payment plans or leasing options that can make acquiring a lathe more manageable. Evaluate the financing terms and choose an option that fits your financial situation, helping you acquire the equipment you need while managing your cash flow.

Buying used lathes for sale can be a strategic and cost-effective approach to acquiring high-quality machining equipment. By carefully considering factors such as machine condition, maintenance history, specifications, and the reputation of the seller, you can make an informed decision that enhances your operational capabilities. At The Equipment Hub, we are dedicated to providing a wide selection of well-maintained used lathes and expert guidance to help you find the perfect machine for your needs. Whether you’re looking to expand your equipment lineup or replace a worn-out lathe, exploring the used lathe market can lead to valuable opportunities and improved performance. Explore our offerings today and discover how a used lathe can be a smart addition to your business.Click Here